Airbus is working on a variety of electric aircraft projects, including electric vertical takeoff and landing (eVTOL) demonstrators, both of which are now being flight tested. Its US-based Airbus project Vahana has so far developed a single-seat demonstrator which began flight testing in January 2018. This May saw the first flight of the CityAirbus, a four-seat air taxi. But the most important of its projects is to develop a hybrid electric propulsion system suitable for use in a 100-seat aircraft by the 2030s.

“Our E-Aircraft Systems Test House is due to enter service this year and shows our commitment to bringing this technology to commercial aviation,” says Glenn Llewellyn, general manager, electrification, at Airbus. “It will be capable of testing electric propulsion systems up to 20MW, the equivalent of one A320 engine.”

The testing facility in Ottobrun, Germany, is 4,500m2 in size and will be able to test electrical systems, batteries, power distribution, electricity generation and gas turbines.

Aritist’s Impression of the E-Aircraft Systems Test House (Image: Airbus)

Construction workers and Airbus employees celebrate the topping out of the new E-Aircraft Systems Test House (Image: Airbus)

“It’s future-proofed in terms of capability – first testing hybrid electric architecture and then fully-electric architecture.

“The building has a lot of hard points for the installation of the heavy equipment needed to test up to 20MW and we have a special thermal and ventilation system that’s built in to manage the specific heat losses that come from hybrid-electric propulsion. We’ve also got electromagnetic screening – it’s a facility that allows us to easily test up to 3,000V and even beyond,” Llewellyn says.

The Grid

Following a similar pathway, Collins Aerospace, which is now part of the USA’s United Technologies Corporation has invested US$50million into building a high-power, high voltage laboratory to design and test more electric aircraft (MEA) systems called The Grid. Currently being built in Rockford, Illinois, USA, The Grid is expected to be fully operational in two years’ time and will be 25,000ft2 in size.

Collins Aerospace’s the Grid laboratory will be dedicated to testing electrical systems

“The Grid is our response to the development of aircraft like the MEA Boeing 787,” says Todd Eckstaine, Collins Aerospace’s director of business development for electric power systems. “We see the industry heading towards more-electric, hybrid-electric propulsion and all-electric propulsion.

“The Grid is going to be a highly flexible platform where we’ll be able to test multiple different electric power ratings and voltage levels.”

Collins’s current largest laboratory has 3,000 horsepower of drive stand capability and can handle systems of up to 540V. The Grid is being designed to have around 8,000 horsepower drive stand capability and run up to the order of 3,000V.

“It’s a two-times step up from the integration labs we’ve had to date. We’re putting in the square footage and the cooling capabilities to future-proof the lab,” says Todd Spierling, chief engineer for advanced technology, United Technologies Advanced Projects (UTAP). “We’re trying to build a lab to serve the industry for the next 20, 30 years, not just the next two or three.”

“We’re not just going to test electrical propulsion systems, we will be testing all of the systems that need to be integrated.

“The lab is being configured to run as one and as separate units that can interconnect. We’ll be able to have half a dozen independent activities going on if that’s the most appropriate use at a given time and connect them together when necessary.”

One of the first projects to take place at The Grid will be work on the UTAP hybrid-electric flight demonstrator, Project 804, which will be based on a Bombardier Dash 8-100. The goal of this project is to re-engine and fly a regional turboprop aircraft powered by a 2MW-class hybrid-electric propulsion system. The Grid will be used to design and test a 1MW motor, a motor controller and battery system which will be used to assist the demonstrator’s fuel-burning engine as part of its hybrid-electric propulsion system.

E-Fan X

Back in Germany, one of the first testing projects at Airbus’s E-Aircraft Systems Test House this year will be for the E-Fan X hybrid-electric flight demonstrator. This project is integrating a 2MW hybrid-electric propulsion system onto a BAE 146 aircraft. The program, which also involves Rolls-Royce and Siemens, was launched in 2017 and aims to demonstrate technology for hybrid-electric single aisle airliners. Its first flight is targeted for 2021.

The E-Fan X demonstrator is planned to make its maiden flight in 2021

Llewellyn says, “Its architecture is made up of several major components including the 2MW electric motor which will be installed under the wing, replacing the gas turbine that powers the fan.

“The motor will be connected to an electric power distribution system and controller. This will manage the power coming from the generator – a gas turbine attached to an electric generator and the battery. The components of this 3,000V, 2MW system will all be tested at our facility.”

Ground testing of systems will start with normal operation and then move onto failure modes.

Electric aviation propulsion firm MagniX is involved in several MEA projects. Its magni250 and magni500 high power-to-weight brushless electric motors are powering Israel-based Eviation’s all-electric aircraft Alice, which is designed to take nine passengers up to 650 miles. The motors are also being used in an electric retrofit of operator Harbour Air’s fleet of de Havilland Canada DHC-2 Beavers.

Harbour Air is based in Vancouver, Canada and its flights average between 40-62 miles and last between 15 to 25 minutes. The CEO of MagniX, Roei Ganzarski, says that a lot of smaller operators would prefer to convert existing aircraft, rather than invest millions into buying new aircraft that can travel further than they need.

“In 2018, 5% of all global flights, 1.8 million trips, were of less than 100 miles, not including cargo and private aviation. All of the aircraft used for these flights are perfectly suited to conversion.

It will be faster and cheaper for the operators working these short routes to convert, plus they can continue to use aircraft they already know. Converting costs 20% of the cost of buying new,” he says.

The magni250 is a 280kW motor that produces 375 horsepower, while the magni500 is a 560kW motor that produces 750 horsepower – both turn at 1,900rpm; the same speed as the propeller. This has allowed MagniX to completely eliminate the need for a gearbox.

“Traditional internal combustion engines turn at much higher speeds to create that power. Because the electric motor turning at 1900rpm creates the same power, you can go directly to the propeller and eliminate the whole gearbox,” says Ganzarski.

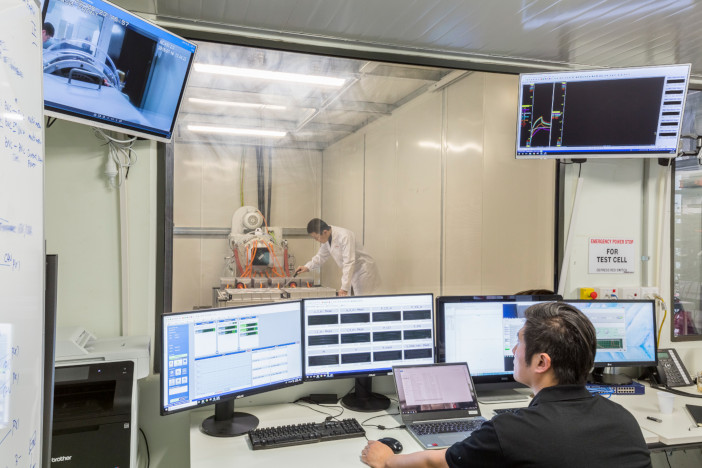

Both motors are currently in assembly and completing ground testing. The first set of tests are taking place in an enclosed test cell, turning against a dynamometer. “That allows you to test in a safe, enclosed fashion. There’s no turning, no propeller and a lot of sensors – temperature, vibration, noise, power. We can ensure the motor performs the way we’ve designed it to,” Ganzarski says.

The MagniX motor is being rigorously tested in enclosed cells

This month MagniX expects to start testing using its iron bird. The iron bird has been developed from the front end of an aircraft, which has had most of its equipment removed and replaced with the electric motor attached directly to the propeller.

Ganzarski says, “The iron bird testing allows us to go beyond testing the motor. We can test the whole system: the motor, cooling, propeller, governor. This is great because it allows for realistic testing right before flight.

“Then, in August we’ll move from the iron bird to integrating the system into the seaplanes and Alice. From there we’ll start ground testing the planes, start low-speed and then high-speed taxiing, before takeoff and then in-flight testing.”

The first test flight is expected to take place this November with certification of the motors expected by the end of 2021 and entry into service by 2022.

The certification requirements are yet

to be made clear, but Ganzarski expects his propulsion systems to be held to the same stringent reliability, consistency and safety levels that the global regulatory authorities expect from today’s non-electric systems.“We expect nothing to be easier because we’re trying something new – on the contrary we expect to have to prove the electric aspect thoroughly, that the batteries are safe and our aircraft are as reliable and safe as traditional craft today, he says.

Regulation versus innovation

Ganzarski doesn’t believe it is possible for regulation to keep up with innovation, nor should they attempt to. “It’s easy for industry to downplay and criticise regulatory bodies for not being flexible, or fast enough, but they have a very hard job, they have to ensure that things are safe.

“However, I do expect that they learn what’s going on ahead of time, so when the time comes to certify they’re ready to go. We’re working with the FAA and they’re very much leaning forward, trying to learn about electronic propulsion.

“Regulators learned a tough lesson with drones. They didn’t know what regulations were needed and there was chaos. But we’ve been in conversation with several regulatory bodies for some time and they’ve been learning, testing, evaluating. They’ve already begun to put together the precursors of what the future regulations will be.”