Siemens is buying US finite element analysis software company MultiMechanics to expand the functionality of its Simcenter software.

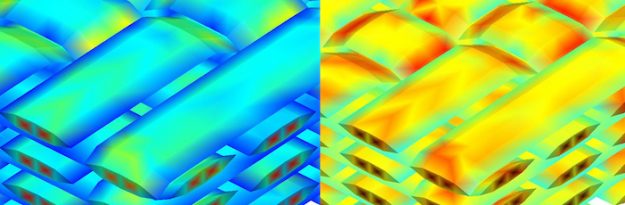

MultiMechanics’ finite element analysis (FEA) software is used to predict material properties and behavior, including at the microstructural level. The technology will be incorporated into Siemens’ Simcenter software within its Xcelerator portfolio, implementing materials engineering into the digital workflow and establishing a link between material developers, manufacturing process developers and part designers.

Jan Leuridan, senior vice president, simulation and test solutions, Siemens Digital Industries Software said, “The addition of this technology enables our customers to build a digital twin of materials, which will help to shrink the innovation cycle of new products and materials, possibly saving millions of dollars and several years in development and certification in aerospace, automotive and other sectors.

“Customers will have the ability to fully exploit the potential of advanced materials to optimize weight and performance in an efficient way that is not possible with classical, test-based, approaches.”

Flavio Souza, president and chief technical officer of MultiMechanics said, “We are excited to join Siemens and the Simcenter family. The combination of our TRUE Multiscale technology in MultiMechanics with Simcenter 3D software will provide a strong basis for further innovation, enabling an expansion of scope of structural simulation to include multi-physics support for applications such as minimization of part distortion, prevention of voids during material flow, and prediction of visco-elastic acoustic properties.”

Siemens said that the acquisition of MultiMechanics expands the capability to create digital twins by integrating structural computer-aided engineering with detailed materials modeling using MultiMechanics’ TRUE Multiscale technology, for a broad range of materials, including polymers, metals, composites, and ceramics.

Digital twins can be used to account for manufacturing variability and imperfections, to identify the root cause of material failure at microstructure level, to optimize material microstructure for best performance, and to enable the creation and virtual testing of new material systems.

“We are confident that as part of Siemens, MultiMechanics’ technology can accelerate innovation in, and adoption of, complex materials, including the further penetration of composites in the automotive and aerospace industries,” said Nicolas Cudré Maroux, chief technology officer of Belgian materials and chemicals company Solvay, a major customer and shareholder of MultiMechanics.

“The accuracy and speed afforded by MultiMechanics, and its efficient integration with commonly used commercial finite element software packages is changing the way we develop new materials and interact with our customers,” added Mike Blair, executive vice president of research and innovation composite materials at Solvay.