Rotating detonation rocket engine for deep space exploration

Propulsion technology represents a key element for the realization of advanced space missions, both as regards the exploration of the Moon and Mars, and as regards the transport of cargo and people to destinations even further away in deep space. To reach this goal, engineers studying new forms of propulsion at NASA developed and tested the first rotary detonation engine, or also known as the RDRE.

The operation of a rotary detonation engine is based on supersonic combustion, known as detonation, which allows it to generate more thrust using less fuel than currently used propulsion systems. The detonations and supersonic waves that are generated inside a combustion chamber are very complex to manage, and therefore the project acquires even more importance given the state of progress.

This technology has been talked about since the 1950s, but to be honest, when it was theorized it seemed more utopian than real, at least until today. This type of engine could be used to power both human landers and interplanetary vehicles for the most distant destinations in space, such as the Moon and Mars, and could represent an alternative to other technologies currently under study, such as the nuclear thermal one of which we have talked about recently.

NASA Marshall Space Flight Center engineers and lead contributor IN Space LLC conducted a test firing on the RDRE in 2022, confirming the data obtained. The RDRE achieved its main goal by demonstrating that its equipment, made with 3D printing techniques, could operate for extended periods while withstanding the extreme conditions generated by detonations. During testing, the RDRE produced approximately 2 tons of thrust for approximately one minute with an average chamber pressure of 47 kg per square inch, the highest pressure level recorded for this type of engine.

The RDRE uses GRCop-42, a copper alloy developed by NASA, and the powder bed fusion process to allow the engine to operate in extreme conditions for longer periods.

The results obtained during the tests represent an important step towards the use of this technology on future spacecraft, which will allow NASA and the commercial space industry in general, to carry ever-increasing payloads to destinations in deep space, a fundamental element to make space exploration more sustainable.

Following the positive results obtained with the RDRE, NASA engineers are working to develop an even more powerful fully reusable RDRE engine, to further identify the performance advantages over traditional liquid engines. We leave you with the video of the incredible rotary detonation engine test.

How Rotating detonation engine works ?

A rotating detonation engine (RDE) is an engine using a form of pressure gain combustion, where one or more detonations continuously travel around an annular channel. Computational simulations and experimental results have shown that the RDE has potential in transport and other applications.

In detonative combustion, the results expand at supersonic speed. It is theoretically more efficient than conventional deflagrative combustion by as much as 25%. Such an efficiency gain would provide major fuel savings.

Disadvantages include instability and noise.

The basic concept of an RDE is a detonation wave that travels around a circular channel (annulus). Fuel and oxidizer are injected into the channel, normally through small holes or slits. A detonation is initiated in the fuel/oxidizer mixture by some form of igniter. After the engine is started, the detonations are self-sustaining. One detonation ignites the fuel/oxidizer mixture, which releases the energy necessary to sustain the detonation. The combustion products expand out of the channel and are pushed out of the channel by the incoming fuel and oxidizer. Although the RDE’s design is similar to the pulse detonation engine (PDE), the RDE is superior because the waves cycle around the chamber, while the PDE requires the chambers to be purged after each pulse.

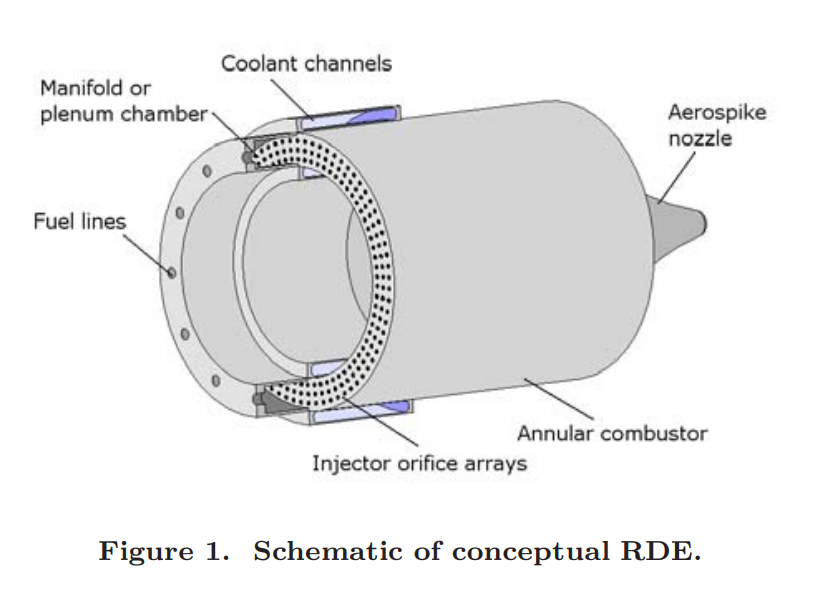

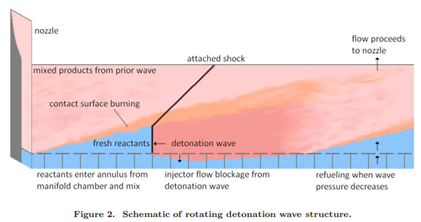

A possible RDE configuration is shown schematically in Fig. 1 while an unwrapped schematic of the rotating detonation wave is shown in Fig. 2. Reactants are fed either separately or premixed into an annular combustor from the bottom. A detonation wave and possibly multiple waves rotate in the annulus just at the exit of the injector arrays, consuming the reactants feeding continuously from the bottom. The high pressure is then reduced to the inlet pressure after passage of the detonation wave which allows the reactants to again feed into the annulus, thereby allowing chemical reactions to continue to sustain the detonation wave. The reactants penetrate a certain distance into the annulus which roughly marks the end of the detonation wave. Further away, the detonation wave degenerates into a blast wave. This structure has previously been called a combined detonation-shock wave35,36 or detonation wavelet. The figure shows a postulated contact surface burning due to the hot environment exceeding the autoignition temperature. Figure 2 shows penetration of the hot, high pressure products just downstream of the detonation wave into the injector. A complex wave interaction is set up, dependent on the properties of the reactants and products, as well as on the geometry of the injector. Preliminary indications are that such a scheme can be operated safely.