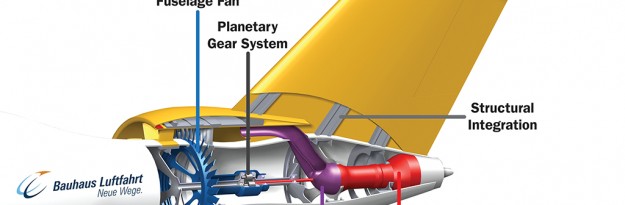

European design house Bauhaus Luftfahrt has revealed new details of its Propulsive Fuselage hybrid-electric concept. The intention is to create a scaled demonstrator as part of the pan-European Clean Sky 2 aerospace research program. This concept has been developed under a European Union-funded Framework 7 research program called Dispursal (distributed propulsion and ultra-high bypass rotor study at aircraft level). The concept is built up by a third gas turbine in the tail, with the scope to filling in the wake behind the fuselage, so reducing drag.

The Dispursal study focused on an Airbus A330-type twin-aisle aircraft for potential entry into service in 2035 or beyond, with 340 passengers. A conventional-configuration year 2035 reference aircraft was developed with ultra-high-bypass-ratio (UHBR) engines, all-electric systems and a fuel-cell auxiliary power unit. This showed a 32% reduction in block fuel burned compared with an A330-300. Bauhaus’s initial study indicated a further increase in efficiency of about 10% for the Propulsive Fuselage concept over the advanced reference aircraft.

Resizing the Propulsive Fuselage aircraft for an optimum long-range cruise speed of Mach 0.78, rather than with the Mach 0.80 cruise used in the original study, increased the benefit over the advance reference aircraft, showing 11% lower block fuel when both were resized. The lower cruise speed would only add 16 min. to an 11-hr. flight at the 8890 Km design range.

The biggest constraint on the performance of the Propulsive Fuselage concept is the weight of the third engine, which provides about 23% of total thrust in the best design. The underwing engines are smaller (2.7 m. dia. versus 3.3 m) because of the reduced drag, saving weight; but the longer fuselage, T tail and aft propulsor all add weight. The weight penalty is covered by the reduction in block fuel. Without fuel, the the weight for the Propulsive Fuselage concept is almost 6% higher than for the advanced reference configuration, but maximum takeoff weight (MTOW) is just 1.3% higher. However, studies showed the structural weight penalty is sensitive to fuselage fan efficiency in distorted flow, which results in MTOW penalties up to 4.6%.

The next steps for this study include more detailed conceptualization of the design, encompassing improved prediction of airframe-propulsion interaction effects and related losses. Fuselage fan performance, particularly surge margin and efficiency, at low speed on takeoff and in abnormal conditions to assess the impact of flow distortion effects will be studied. An opportunity for testing the concept could occur as part of Clean Sky 2, which aims to mature technology for an advanced airliner to enter service after 2030. In its third call for core partners, the research program is seeking participants to perform “divergent aircraft” configuration studies focused on hybrid electric propulsion and to help validate flight testing of a dynamically scaled model as a lower-cost way of identifying the performance of the full-size aircraft.

Clean Sky 2 is a government/industry research program with an investement of €4 billion ($4.5 billion) from that will run from 2014 to 2024. Clean Sky 2 has identified distributed propulsion using hybrid power transmission—gas turbines driving electrically powered fans tightly integrated with the airframe—as the likely optimum solution to meet Europe’s Flightpath 2050 environmental targets. Clean Sky 2 aims to a radical aircraft designs, involving Airbus, Dassault, Saab and Snecma. Airbus and its partners also plan to demonstrate a fully integrated UHBR engine, Rolls-Royce’s UltraFan large geared turbofan, on a flying testbed in 2018. But the more highly integrated hybrid propulsion configuration would be vetted using an unmanned subscale aircraft, to reduce cost, time and risk. The schedule calls for flight testing by late 2022.