Soon the space companies could begin in-orbit manufacturing and assembly of communications satellite reflectors or other large structures, according to Made in Space, the Silicon Valley startup that sent the first 3D printer to the International Space Station in 2014.

This company has an ambitious goal to build a 3D printer equipped with a robotic arm (so called Archinauts) with plans to install in an external space station pod, under a two-year. The NASA will provide financing of $20 million. The project will culminate in 2018 with an on-orbit demonstration of Archinaut’s ability to additively manufacture and assemble a large complex structure. Archinaut was one of three projects NASA selected in November that focus on robotic manufacturing and assembly of spacecraft and structures in orbit, and also as part of its Tipping Points campaign, which funds demonstrations of space-related technologies to offer significant payoffs for government and commercial applications. Actually it is necessary to spend milions of dollar to send satellite by using expensive and complicated rockets, the Nasa is seeking to create an infrastructure to build systems in space rather than launching them.

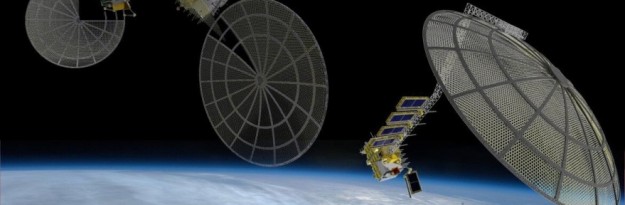

That type of infrastructure would enable NASA and private space companies to launch the raw materials used in additive manufacturing along with certain high-value components like sensors, electronics and batteries. Once in orbit, robotic arms would mate the parts sent from Earth with additively manufactured elements. If on-orbit manufacturing and assembly are possible, they could revolutionize spacecraft design because engineers would no longer need to create structures capable of withstanding the force of Earth’s gravity before they launch, fitting inside a rocket fairing or withstanding the vibration and acoustic forces of launch.

Archinaut is a first step on that path. Made in Space is building Archinaut’s 3D printer, which it plans to mate with a manipulator arm built by Oceaneering Space Systems. Northrop Grumman is providing systems engineering, control electronics, software, testing and assistance with Archinaut’s space station interface. Eventually, the companies envision a version of Archinaut with three robotic arms capable of latching onto orbiting structures to add or remove components, which eventually would enable companies to remove parts from decommissioned spacecraft and use the parts in new spacecraft. This solution offers the added benefit of cleaning up debris, and will knock down the costs significatively by the reusing parts already in the orbit.