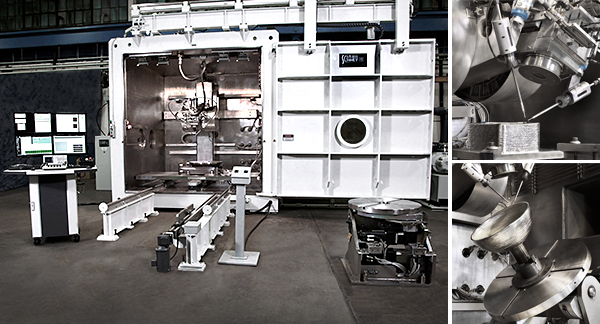

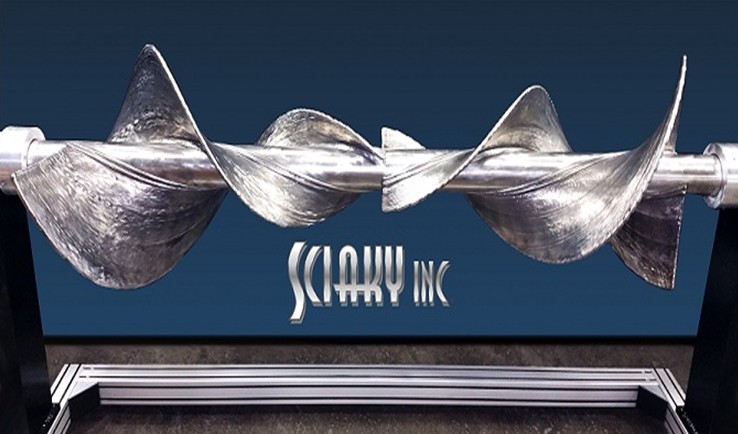

In a production site in France Airbus is installing a manufacturing machine to product 3-D-print titanium aircraft structural parts. This machine (EBAM 110, electron-beam additive manufacturing) is producted by U.S. company, Sciaky, and is expected to be commissioned in February. Developed from decades of electron-beam welding experience, Sciaky’s EBAM machine builds metal parts layer by layer by melting metal wire using an articulated, moving electric-beam gun, and it is large enough to produce airframe structural components (any part inside an aircraft engine).

This tecnology is still in its infancy, and most of Sciaky’s activity so far has been focused on qualifying materials, processes and parts for customers such as Airbus and Lockheed Martin. Five EBAM machines have been built, including the one for Airbus. The fifth will be delivered this month to the Buffalo Manufacturing Works at the University of Buffalo, New York.

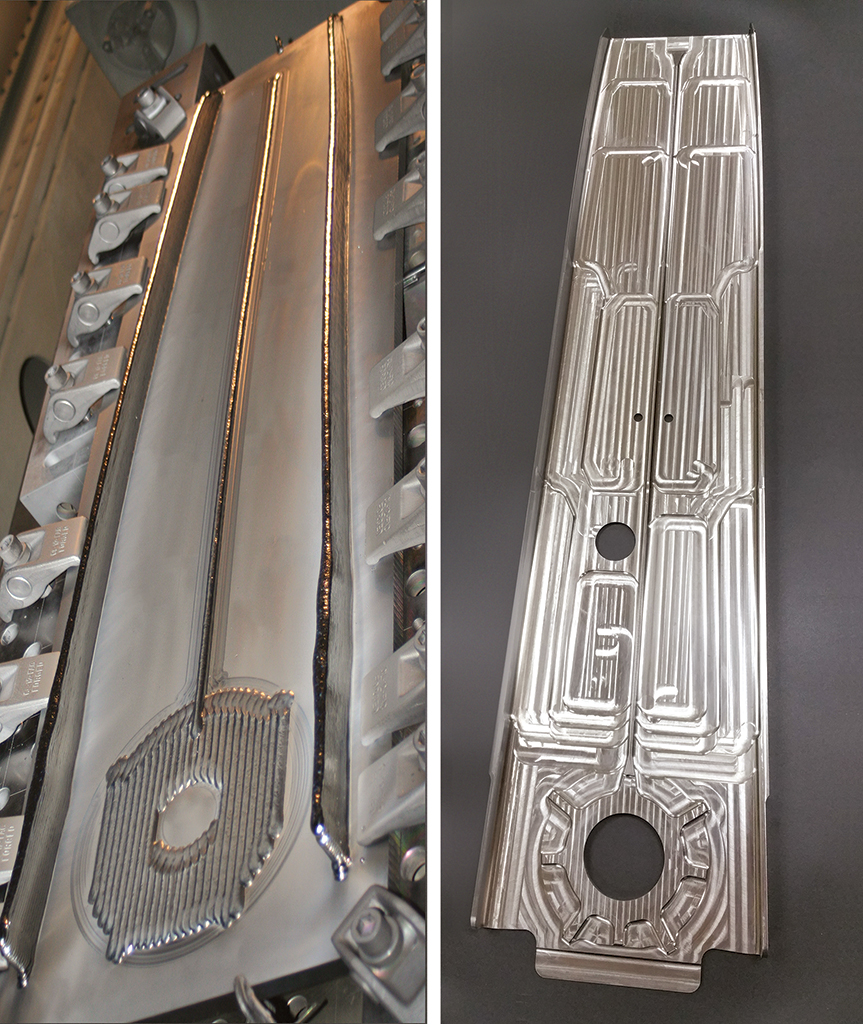

The tests completed so levitra 40 mg generic far shows EBAM can produce components that meet or exceed the properties of forged parts. Printing rather than forging avoids the long lead times and the waste of expensive metal involved in machining finished parts from forgings. EBAM can produce parts in hours or days, versus weeks or months. Below is shown a Rear Spar realized for Airbus (on the left, on the right is the same lightly machined to refine the part).

Sciaky is developing the capability to handle other metals used by the aerospace industry, as Inconel and Hastelloy used in the hot sections of engines, and also high-temperature refractory metals used in rocket nozzles. Lockheed Martin will use some part realized by EBAM on airframe structures for the F-35, for its for use in its satellites (Lockheed Martin Space Systems).